Click here to shop for VCWS 4 Upper Extremity Range of Motion parts and supplies

Purpose: To assess upper extremity range of motion and work tolerance in the upper body, including shoulders, arms, elbows, wrists, hands, and fingers. The work sample simulates light work and makes the following physical demands upon the evaluee: reaching, fingering, feeling, near acuity, depth perception, accommodation, and color vision. Significant motor coordination and manual dexterity are called for in order to perform the work sample at a competitive level.

The work sample elicits information on several secondary, work-related characteristics, including the ability to follow instructions, physical stamina, level of motivation, communication skills, and self-confidence.

The evaluee’s level of fatigue and/or pain are assessed twice during the work sample administration and recorded on a color-coded upper extremity body chart.

The work sample is very well suited to various work- hardening uses.

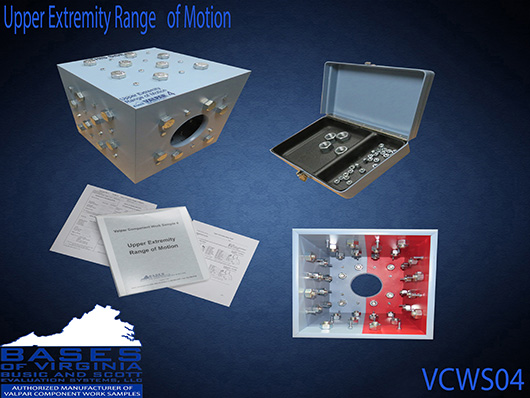

Design: Two different sized nuts are assembled onto bolts using only the fingers.

Special Features: Scores may be interpreted against criterion-referenced standards, supplied norms, or locally developed norms. It is appropriate for use with disabled or nondisabled persons. A VCWS#4 B-Kit — adaptations for visually impaired or blind persons — is available.

Information Collected: The work sample has been analyzed according to U.S. Department of Labor job analysis techniques. The result of the analysis is a list of rated DOL work-related abilities and other factors that are required for successful work sample performance. Valpar uses Methods-Time Measurement (MTM) to establish industrial work rate standards for the work sample. Successful performance requires a variety of DOL aptitudes, physical demands, and other factors.

The evaluator uses learning curve adjusted MTM standards to determine whether the evaluee has demonstrated the work sample’s Worker Qualifications Profile. Adjusted MTM standards for individual exercises are provided as well. Unadjusted MTM standards are also given for individual exercise administrations of the work sample.

Procedures: The work sample is usually administered with the evaluee in a standing position. There are eight assembly exercises (four each for the right and left hands), and one disassembly exercise for both hands. The evaluee picks up one nut at a time, reaches through the opening in the front of the work box, positions the nut, and screws it down snugly against the box. The inside of the box is divided into red and blue halves. The right hand works the red side of the box first; the left hand works the blue side of the box second. Finally, the evaluee removes the nuts using one hand at a time and places them back into the storage compartment.

The evaluator assesses the evaluee’s fatigue and/or pain after both the right hand and left hand portions of the work sample.

Components: The work box is a 12″ cube with an open back end and a 5″ opening in the front. The five sides of the box are lined with machine bolts of various sizes, threads exposed to the inside. A box for storing the nuts is included. The bolts and nuts are zinc plated to inhibit rust and tarnish. The work sample comes with manual, a pad of 100 scoring sheets, and a pad of 100 body charts.

Shipping Size and Weight: 1 carton @ 16″ x 16″ x 16″ – 38 lbs.